FOB Price

Get Latest Price0 ~ 1.5 USD

|5000 Minimum Order

Country:

China

Model No:

401

FOB Price:

0 ~ 1.5 USD Get Latest Price

Place of Origin:

Shangdong, China

Price for Minimum Order:

-

Minimum Order Quantity:

5000

Packaging Detail:

20g/bottle*10 bottles/intermediate box*10 intermediate boxes/case=100 bottles/case

Delivery Time:

(7-15 days) depending on the order quantity

Supplying Ability:

500000 per Month

Payment Type:

Western Union, L/C, T/T

Product Group :

Contact Person Ms. Tina

NORTH OF CHUANGYE STREET, HIGH AND NEW TECHNOLOGY INDUSTRIAL DEVELOPMENT ZONE, Yucheng, Shandong

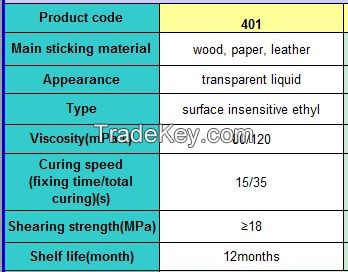

Model 401 is a universal, moderate-viscosity and high-strength

α-ethyl cyanoacrylate adhesive.

Be

suitable for closely conglutinating porous materials, for example

metal plastic, rubber, eraser, wood, leather,

ceramics and wood,

with the strongest binding effect; Used for conglutinating porous,

acidic and absorbent materials, be insensitive to surfaces and may

be used for difficult-adhesive

surfaces.

Packing specification:

20g/bottle * 10

bottles/intermediate box * 10

intermediate boxes/case=100 bottles/case

Package size:

38.5*25.5*12.5cm

Storage:the product is

placed and sealed in the original package and stored at a cool

place protected from direct sunlight irradiation and from long-term

air contact (can be

refrigerated in a refrigerator for extending preservation

time).

Conventional package:

20g/bottle, 20kg/bucket

Safety attentions: Dangerous

and irritant gas is prevented from contact with eyes and

skins. Otherwise, it will adhere to skins within several

seconds. In case of contact with eyes, wash eyes with plenty of

fresh water for 15 minutes and immediately seek medical assistance.

It is used in a well-ventilated place, and its contact with clothes

shall be avoided, otherwise a large amount of heat generated will

burn skin. Kept out of reach of children.

Precautions:

1. The

surface of adhered materials is wiped with organic solvent such as

acetone to remove grease or release agent. It shall be noted that

salt-base substances (water, alcohol, amine,

etc.) residual

on the surface after treatment may accelerate curing of the

adhesive and acidic substance residual may slow its curing rate.

Therefore, the surface must be thoroughly

cleaned.

2.

Adhesive application amount must be appropriate. Generally, thinner

adhesive layer causes higher strength; in case of more application

amount, required moisture is more and curing rate is slower;

Therefore, for compact, good-contact plat boards, adhesive

application amount of 4-5mg/cm3 is adequate.

3. If the

gap between base materials is smaller, curing rate is larger.

Therefore, it is recommended that the gap between adhered materials

shall be between 0 and 0.1mm, and Yuwang adhesion accelerator or

thickened adhesive is used for the gap over

0.1mm.

4.

Superimposition cant be conducted immediately after adhesive

application, and airing is conducted for 1-5s, depending on air

humidity; During adhesion, operate at the aligned position and

prevent dislocation. Otherwise, adhesion strength will be

influenced. Compression time is generally

2s-5min.

5. Curing

rate is related to the temperature and humility of adhered

position. High temperature and high humility cause large curing

rate and reduced adhesion strength. The most appropriate

temperature is 20-30℃ and

most appropriate humility is 50-60%. The humility over 70% must be

avoided, otherwise whitening phenomenon will occur. Both excessive

dryness and excessive moisture will influence curing rate and

adhesion strength.

6. If

adhesion time is too long due to larger gap between base materials

or lower environmental humidity, it is feasible to use Yuwang

adhesion accelerator (add 25mg accelerator into each 20g

adhesive).

7. The

adhered material has better permeability, the adhesive with larger

viscosity will be more appropriate.

8. For

difficult-adhesion materials such as PE, PP, silica gel, ABS and

TPR, after their surfaces are treated with Yuwang treating agent

sprayed, their adhesion effectiveness is

better.

9.

Vaporing adhesive

gas combines with the moisture in air to cure into a white powder,

namely whitening phenomenon. If a customer proposes the restrict

requirement of whitening phenomenon, it is feasible to use products

with low whitening potential, or strengthen the air circulation or

use the corresponding promoter to reduce whitening

potential.

10. For a

small area of glue, glue layer may be softened by warm water

soaking or removed with acetone.

| Country: | China |

| Model No: | 401 |

| FOB Price: | 0 ~ 1.5 Get Latest Price |

| Place of Origin: | Shangdong, China |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 5000 |

| Packaging Detail: | 20g/bottle*10 bottles/intermediate box*10 intermediate boxes/case=100 bottles/case |

| Delivery Time: | (7-15 days) depending on the order quantity |

| Supplying Ability: | 500000 per Month |

| Payment Type: | Western Union, L/C, T/T |

| Product Group : | Acrylates |